Dry tea technology research

Although the drying process is the last step in the processing of major teas, it plays an important role in the formation and fixation of the quality of tea.

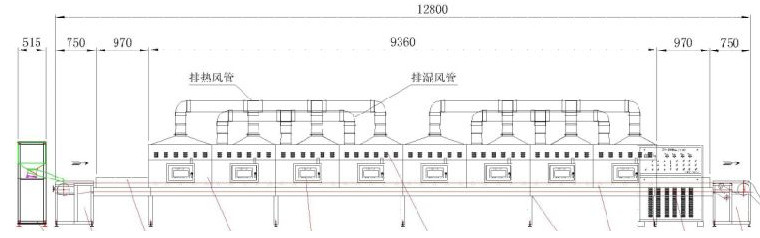

At present, some newer drying technologies suitable for the tea industry have been slowly used in the tea industry, mainly including microwave drying, infrared drying, far infrared drying, vacuum freeze drying, vacuum low temperature drying and the like. The microwave drying machinery and equipment processing technology suitable for the development of China's current tea industry contributes to the formation of high quality tea products.

Therefore, how to do a good drying process will play a vital role in the quality of Maocha.

The main purpose of the microwave dryer process is to lose moisture in the tea leaves after the mash (or wrap) to facilitate the formation and storage of the tea leaves. Appropriate drying treatment can also improve the quality of the tea, so that the tea can be upgraded in a level of sensory quality and content. According to the research, the drying process can increase the content of linalool and its oxides, geraniol, methyl salicylate and α-terpineol in tea, and these components are all part of the tea aroma components. .

The increase in the content of these ingredients plays an important role in the improvement of the quality of tea. In the traditional drying process, the content of polyphenols in tea does not change significantly. Amino acids, soluble proteins and soluble sugars are somewhat affected by heat treatment, resulting in a slight decrease in the content.

The traditional drying technology of tea starts from charcoal baking and slowly evolves into coal roasting, liquefied gas roasting, etc. The technical requirements required for drying with charcoal are high. It requires an experienced master to carry out. Otherwise, it is likely Tea leaves have odors such as smoke and coke, which in turn reduces the quality of the tea. The principle of coal baking and carbon baking is almost the same, mainly to improve the work efficiency, without frequent fire.

Thermal drying is another breakthrough in tea processing, making the tea drying process truly enter the era of clean energy. Electrothermal drying equipment commonly used are electric baking boxes, incense machines and the like.

The principle is that the air is heated by blasting in the hot air, and the moisture of the tea leaves is evaporated by the contact of the hot air with the flow of the tea material, thereby achieving the drying effect. Electrothermal drying needs to take into account the uniformity of the heating of the tea leaves so that the tea leaves can be dried evenly. Due to the mature process of electrothermal drying, the drying capacity is large, the drying time is short, and the equipment cost is low, which is easily accepted by tea farmers.