Development and application of hydraulic press

Industrial oil press machine is a series of general-purpose pressing equipment, such as powder molding, plastic molding, cold (hot) extrusion metal molding, sheet drawing and stamping, bending, flanging, calibration and other processes, is widely used in electronics, hardware and automotive industries.

With the development of hydraulic technology, PLC control technology and microwave drying machinery and equipment, most hydraulic presses have realized automatic control, but for the work of loading and unloading with hydraulic presses, most enterprises still operate manually. For heavy and heavy workpieces, the loading and unloading not only has high labor intensity, but also has high operational risk factor. At the same time, because of the need for loading and unloading, two people need to cooperate with each other to achieve low production efficiency and high production cost.

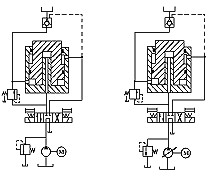

Through the analysis of the working condition of the hydraulic press in the enterprise, the necessity and inevitability of the automatic upgrading of the loading and unloading process of the hydraulic press are put forward. According to the actual production requirements of the enterprise, the overall mechanical structure design of the loading and unloading device of the hydraulic press is carried out. In the mechanical structure, several typical structures such as sprocket drive, synchronous belt drive, rack drive and screw drive are adopted, which make the device compact, flexible and portable.

The control system of the device is mainly composed of PLC, touch screen and servo drive. It can realize the automatic production of loading and unloading process, realize the precise cooperation between loading and unloading device and hydraulic press, and achieve the goal of improving production efficiency, reducing production cost and reducing the operation risk of workers.

The company has developed a set of automatic loading and unloading equipment based on hydraulic press, which adopts the mechanical structure of sprocket drive, synchronous belt drive, gear rack drive and screw drive, combined with pneumatic transmission system, controlled by PLC control system, and basically realizes the unattended operation on the working station of hydraulic press in entrusted enterprise. Achieve the goal of improving the production efficiency of hydraulic press, reducing production costs and reducing workers' operational risk.

According to the working characteristics of hydraulic press, this paper designs and manufactures a selection scheme for how to satisfy the dynamic and changeable customer demand with lower cost and faster speed by using multiple transmission, and improves the customer satisfaction. At the same time, it also improves the innovative ability of these customized enterprises, and realizes both individualized customization and phase for enterprises. It provides effective and feasible methods and paths for reducing the production cost of enterprises. However, it should be noted that the application of this research results need strong support of information technology in order to achieve the desired results.