Application of microwave vacuum drying technology in food industry

Industrial microwave vacuum dryer technology is very suitable for dry food production.

However, the design of microwave drying machinery and equipment is based on the theory of electromagnetic wave transmission. The technicians engaged in the design of equipment generally do not understand the food technology and characteristics. However, a lot of experience accumulated by the researchers of food technology can not be completely transplanted into the microwave heating system. The combination of the two needs a certain time. This is another reason for the rapid popularization of microwave vacuum drying technology in the food industry.

Compared with foreign microwave vacuum equipment, the technology of industrial microwave vacuum dryer is not inferior. With the continuous improvement of computer automatic monitoring and control level of microwave vacuum drying equipment, microwave vacuum drying technology will be more widely used in food production.

Microwave vacuum drying technology has great potential in other food processing fields.

At present, Lin et al. [18] have carried out the experiment of microwave vacuum drying shrimp, and compared the quality of microwave vacuum drying shrimp with that of hot air drying and freeze drying shrimp. It is found that the shrimp dried by microwave vacuum has a smaller yield, stronger water rehydration and moisture retention ability than that dried by hot air drying, and has a better color and texture. Flavor and other aspects are similar to the rehydration of frozen shrimps. The drying experiment of scallop was carried out with the self-made microwave vacuum drying equipment. The results showed that the color, aroma, taste and drying time of the dried scallop were all satisfactory.

In recent years, the application of microcomputer technology has developed rapidly. The application of MCS-51 series microcontroller integrated circuit system with high performance and low price provides good conditions for realizing the automatic program of high power microwave power supply.

Using microcomputer control can not only realize the automation of operation program, but also optimize the real-time control of power supply system. It can give full play to the characteristics of fast adjustment of microwave power, inertia-free and easy to control in real time.

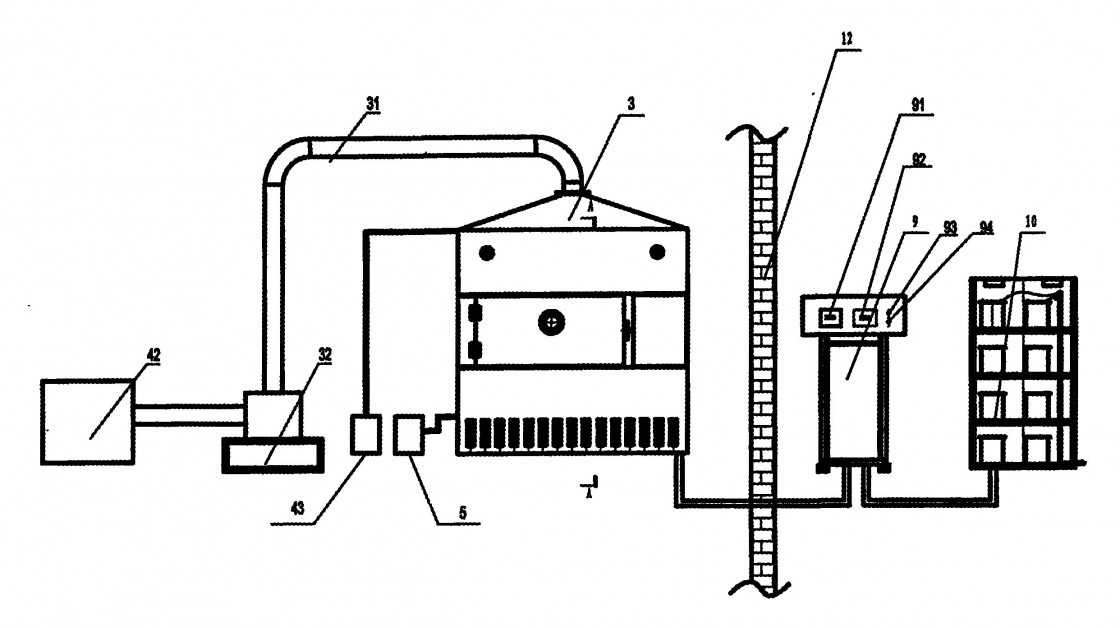

In the microwave vacuum drying test equipment, data acquisition module of DUT series and multi-channel sensor are used to transfer data to PC through RS-485 bus and standard communication protocol. With the support of software, visualization can be realized, man-machine conversation can be carried out, temperature, vacuum and weight of materials can be displayed on-line, and real-time monitoring can be realized. The earth is convenient for experimental research.