Performance optimization of diesel engine burning B20 biodiesel

With the development of the world economy, environmental problems such as energy shortage, air pollution and climate change have brought enormous challenges to the development of global industry. Seeking alternative fuels is one of the effective ways to solve the shortage of petrochemical energy.

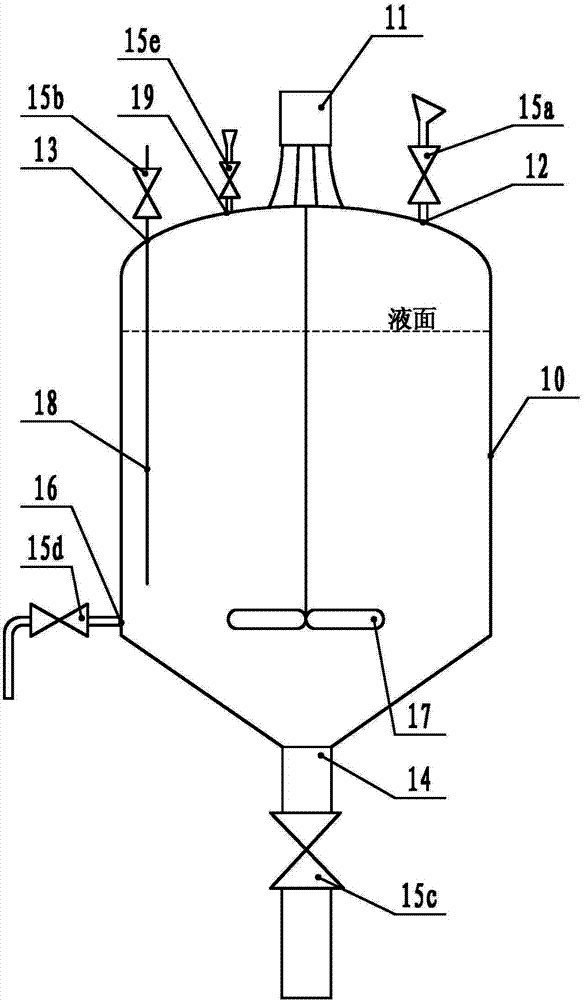

Microwave drying machinery technology

As an effective liquid alternative energy source, biodiesel plant has a wide range of sources and distribution. It uses biodiesel fuel to reduce soot and hydrocarbon emissions from combustion.

Experts and scholars at home and abroad have carried out a large number of experimental studies on the physical and chemical properties of biodiesel and the performance and emission characteristics of biodiesel. The research shows that: fuel density, viscosity and cetane number increase with the increase of biodiesel blending ratio; The value decreases as the biodiesel blending ratio increases.

Among them, the combustion of high proportion biodiesel has great influence on the economical and dynamic characteristics of the machine. It is not suitable for blending directly in the diesel engine and must be rematched with the electronically controlled fuel system. Therefore, the biodiesel fuel currently used in the market is mainly based on a low volume content ratio. Therefore, this paper selects a biodiesel fuel with a volume content of 20% (abbreviated as B20) for research.

in conclusion

(1) Burning diesel engine under external characteristic conditions B20 biodiesel simulation calculation, the comparison of power and specific fuel consumption test value and simulation value is in good agreement, and the accuracy of the simulation model is verified;

(2) The test design scheme is described. The test parameters are arranged by the Latin hypercube test design method for the control parameters, and the simulation calculations are performed under the steady state cycle.

(3) Based on the calculation results, using the RBF neural network to establish a model between the test factor and the response variable, the decision coefficients of the three response variables are all close to 1, indicating the accuracy of the modeling;

4.Based on the model for multi-objective genetic optimization, the two schemes before and after the optimization were compared, and the NOx was reduced by an average of 17. 2%, the fuel consumption rate is reduced by an average of 4. 2%, soot increased by 2.5%.