Potato slicer

Potato is a common vegetable, which is mainly used for fresh food in daily life; in industry, it is mainly processed into starch, vermicelli, powder skin by various processing technologies, and some of it is processed into familiar convenience food (potato chips, potato chips).

Microwave drying machinery and equipment

With the improvement of people's living standards, new requirements for the quality of life have been put forward, and the fast food industry has developed rapidly. The consumption of leisure food such as potato chips and chips has increased dramatically, which has promoted the further development of potato production and processing industry. In many industrial processes of potatoes, it is often necessary to slice potatoes quickly, but it is difficult to complete a large number of potato slicing in a short time by manual work, which requires finding other efficient ways to complete the slicing of potatoes.

In the design of potato slicer, the whole structure is built through system analysis, and the design of each part of the slicer is completed. Then the mechanical structure of the potato slicer is modeled by UG software, and the results of the modelling are imported into the CAD plane line processing. The actual processing of parts and components is completed by mechanical processing method. Finally, according to zero. Assembly with matching relationship.

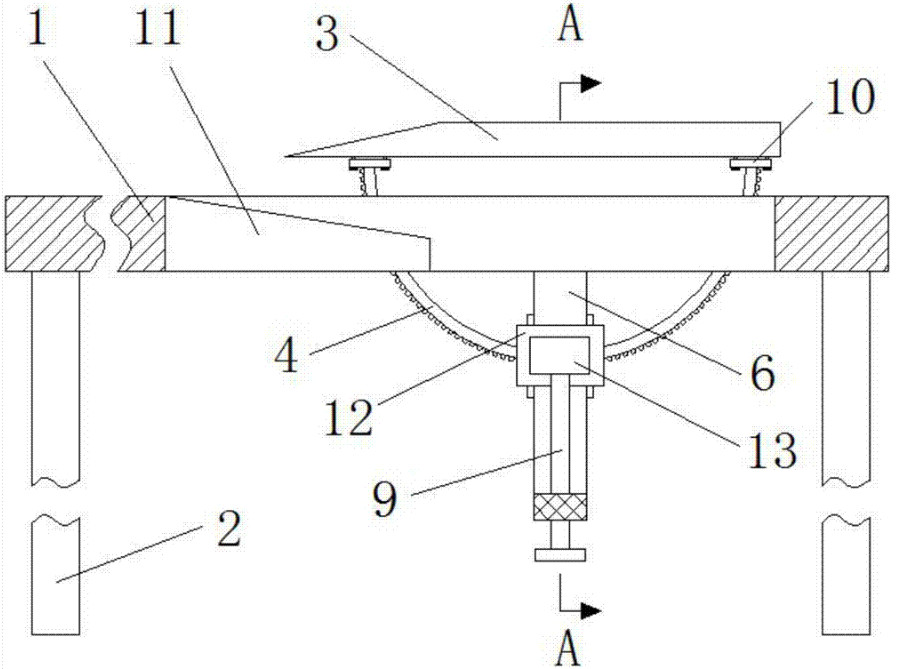

Composition of potato slicer

The potato slicing machine is made up of shaft, bearing, key, V belt, pulley, blade and rack. This design adopts Y90L-4 motor with power of 1.5 kW and speed of 1 500 r/min. After the motor reduces through the cutter belt, the power is transmitted to the output shaft. The top of the shaft is connected with impeller and blade. The blade can cut the material into slices, and the cut material falls from the bottom of the cutter head, and then is sent out through the outlet. The thickness of the slice can be controlled by adjusting the thickness of the gasket between the blade and the turntable.

Blade type selection

There are two kinds of cutting blades: straight-edged blade and round-edged blade. The force of straight-edged blade and round-edged blade in cutting is analyzed.

In this design, force analysis will be carried out on the blades of common types, and the blade type and frame design suitable for this type of centrifugal slicer will be selected.

Rack design requirements

The rack needs to provide a stable working environment for the operation of the slicer, so the design of the rack should meet the following three requirements:

(1) sufficient strength and stiffness;

(2) the shape is simple and easy to manufacture;

(3) it is convenient to install accessories on the rack.

Stiffness determines the working capacity of the rack. Stiffness in the centrifugal slicer determines the production efficiency and cutting accuracy of the slicer. Stability is the basic condition to ensure the normal operation of the rack.

In order to meet the requirements of stable slicing and cutting efficiency, the centrifugal slicing machine designed should meet the following functional requirements:

(1) under the premise of meeting the strength and rigidity, the quality of the rack is light and the cost is low.

(2) good resistance to vibration.

(3) the noise is small.

(4) the distribution of temperature field is reasonable, and the influence of thermal deformation on accuracy is small.

(5) the structure design is reasonable and the process is good, so it is convenient for casting, welding and machining.

(6) the structure is convenient for installation, adjustment and maintenance.

(7) the guide rail is reasonable in force and good in wear resistance.