Key technologies of twin screw extruder

In the 1980s, China introduced twin-screw extruder technology and applied it to plastic modification engineering. In the past 30 years, after continuous technological digestion and technological innovation, China's twin-screw extruder manufacturing enterprises have continuously matured and developed, and occupied a higher market share in the international market, and in engineering plastics, rubber. Rubber, food, paper and other industries are widely used.

Microwave drying machinery and equipment

Especially in the engineering plastics industry, laboratory twin screw extruder has become the main equipment for plastic modification, reinforcement and blending extrusion.

The basic requirements for equipment include the following 5 points:

1) Quality: Quality is the most important thing for users. The quality of extruded products is a commitment to customers, is the life of enterprises, and is closely related to the development of enterprises. Therefore, it is an important index to evaluate the quality of an extruder whether the consistency of products in different batches can be guaranteed for a long time.

Efficiency: Efficiency is a further evaluation index. On the basis of guaranteeing quality, the highest product yield per unit time is the goal pursued by every enterprise. It is also the only way for the rapid development of enterprises. High-speed and high-efficiency extruder is one of the main development directions of extruder manufacturing technology.

2) Cost: Increasing efficiency itself is one of the means to reduce costs. Increasing efficiency directly reduces the energy consumption of water, electricity and gas per unit time, that is to say, it reduces the operation cost. At the same time, the human cost and management cost that enterprises are most concerned about are reduced accordingly, and the demand for equipment and land is reduced accordingly.

3) Durability: Efficiency is inversely proportional to life. Increasing efficiency may lead to reduced service life. In order to ensure or increase service life under the premise of high efficiency, more durable materials are needed, that is, screw materials with high wear resistance and high strength core shafts.

4) Practical: From the user's point of view, whether the equipment is easy to operate and maintain, whether the equipment can run steadily, the failure rate is high or low, which is also one of the indicators to evaluate the quality of an extruder.

To sum up, quality and efficiency are two decisive important indicators. How to "guarantee quality" and "improve efficiency" are the goals of extruder development for many years.

The key technology of 1 twin screw extruder

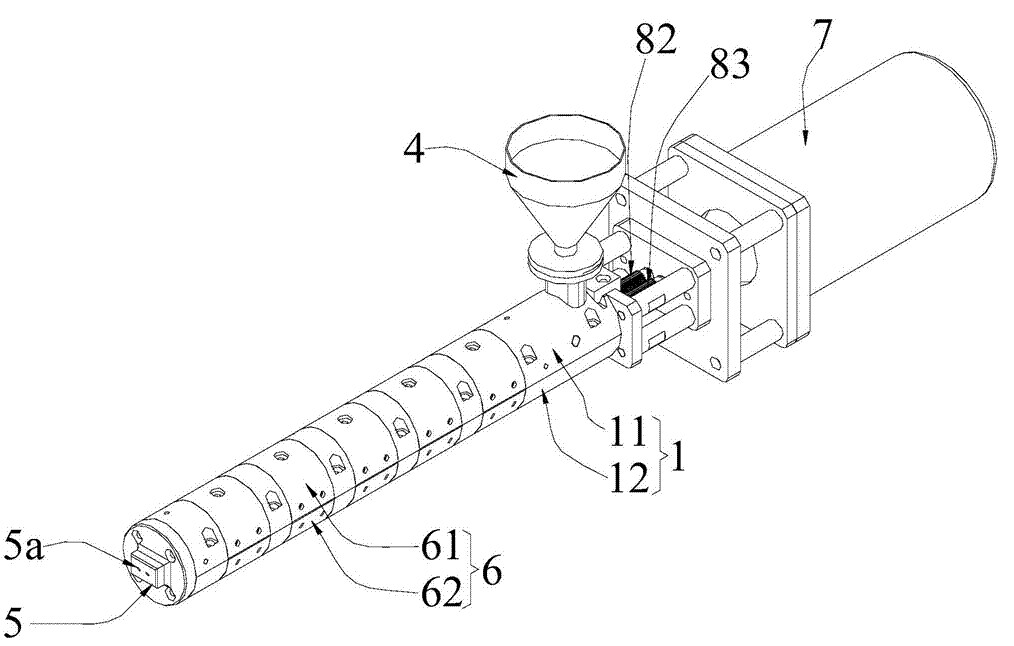

The twin screw extruder is divided into two key parts: extrusion and transmission. The extrusion component is the key component to ensure the quality. The transmission component is the key component to improve the efficiency and guarantee the quality. The technological progress of twin screw is marked by the renewal of torque distribution box, which shows its importance.

1.1 transmission technology

Driving parts are the core components of twin screw extruder. Like the engine of automobile, they can provide enough power to output enough output. Therefore, to improve the extrusion efficiency, a strong driving system is needed to provide power. In twin-screw extruder, power is reflected by the rotating motion of screw elements. In rotating motion, kinetic energy is transformed into torsional force. The larger the torsional force, the more materials are transported, that is, the power of high-torque transmission system is needed to achieve high output. According to the current development of extruder industry, the transmission system is divided into two representative typical structures: parallel triaxial gear structure and bilateral symmetrical drive gear structure. Through the analysis below, we can see the difference between the two structures.